Product Line History

1996–1998

1996

PhiBer began when Phil Friesen and Harvey Bergen developed the Strawboss. The Strawboss gave ginseng producers the ability to spread large square bales instead of small ones. This helped reduce a crew of about 30 people down to 2, while tripling productivity—resulting in significant labor savings.

1997

The Bale Grab is introduced to speed up the handling time of bales in the field. Originally designed for single bales, PhiBer has since developed over 11 models to accommodate PhiBer’s Accumulator capacity, meeting a variety of bale-handling needs across different loaders and bale sizes.

1998

The Swath Turner is introduced and designed to bring two windrows of alfalfa together and invert them, while being gentle on the alfalfa leaves. This method reduced ash content in the hay, resulting in faster drying times. Less ash helped alleviate respiratory issues in horses and allowed dairy cows to absorb more nutrition from their feed.

2000–2002

2000

PhiBer introduced the first fully automatic Bale Accumulator, designed for simplicity and compatibility with both silage and dry hay. Co-founder Phil believed the best way to remove bales from the field was to accumulate them based on how they’d be handled—an idea that still guides PhiBer’s designs and leadership in big-bale handling.

2001

The 02 Series Bale Accumulator was introduced with improvements to both the electronic and hydraulic systems, as well as upgraded casters.

2002

In an effort to expand the business, PhiBer began manufacturing and selling the Bale Boss under a licensing agreement. Designed to spread straw bales, the machine remained in production for three years. After a downturn in the beef market, PhiBer discontinued production.

2003–2006

2003

04 Series Bale Accumulator was developed with operators and the wide range baling conditions in mind. Improvements included faster hydraulics, improved software for automatic dump patterns, heavier castors and frames and options for VT interfaces with Case New Holland. The 04 Series was in production for 11 years.

2005

The Merger, originally called Swath Turner, was updated with a new, bright yellow frame and modifications allowed up to 5 rows to be merged into one. A simple push of an automatic transport button made transitioning from field to road seamless.

2006

Renamed for a 3rd time, to the Super Merger, as it is called today, saw improvements to the pickups and drapers, increasing capacity in all silage conditions and improving operator friendliness, making adjustments and services easier.

2007-2011

2007

Evolving out of the changes made to the Super Merger, the Super Single was designed to support the new pickups and drapers. A draper extension was also developed to allow operators to merge up to three rows into one.

2009

Developed for Co-Founder Phil Friesen’s Farm, by son Derek, the Triple Cutter was a result of frustratingly high fuel prices and a desire to reduce fuel bills for cutting. The Triple Cutter reduced fuel consumption by 60–75% while having the capacity to cut up to 600 ac/day with one operator.

2011

Born out of the Triple Cutter, the Front Toolbar was developed and allowed farmers to connect their own, additional application and pair it with their traditional pull type conditioner. To accommodate the different pull type conditioners, different hydraulic systems were developed.

2012-2015

2012

Changing the way big bales are handled, stacked and stored, the Stacking Vertical Accumulator stacked 4’ wide bales in a uniform package, 2 or 3 bales high. Cutting the handling time in half over traditional accumulation methods and four times faster than picking single bales.

2014

The 06 Series Bale Accumulator was faster, more reliable, and capable of working in a wider range of conditions. The 06 Series featured a new hydraulic package, improved electronics and sensors, new lighting, improved rear roller assembly and new safety features to protect operators and service personnel.

2015

Created to complement the Stacking Accumulator, the Big Bale Spear was launched. Designed for vertical lifting only, the heavy frame attaches to telehandlers and wheel loaders and has three bale spikes and eight cast bale hooks to easily go in and out of bales.

2016-2017

2016

Focused on technology improvements and integrations, PhiBer launched a new vertical accumulator, the VS 1204 and two, new horizontal accumulators, the AC 3108 and AC 4108, all with ISOBUS capabilities and Bluetooth integration to the new PhiBer App.

2016

The PhiBer Accumulator App was developed to give the operator more freedom and functionality. The PhiBer Accumulator App can function as a remote control for any hydraulic function and allows for users to directly connect with PhiBer’s team, plan bale eject patterns and automatically eject bales.

2017

PhiBer had a busy and productive year, launching a new vertical stacker series, VS 1206, using ‘Smart Gate Technology’ with an ultrasonic sensor and split lift arms. The PhiBer Accumulator App was updated to include WiFi connectivity and software improvements.

2017-2019

2017

Two other completely new product lines were launched, the Gladiator, designed to reclaim substandard land lost to high moisture levels and the DASH 4.0, reinventing the way chemicals are handled, mixed, and loaded into sprayer, reducing fill times to 4 minutes.

2018

The DASH 2.0 was launched with all the features as its big brother, DASH 4.0, but in a smaller package, with only 2 inductors, opposed to the 4 found on the 4.0.

2019

In response to customer requests for a turnkey solution, the DASH Complete Trailer Package was released, giving customers the ability to take advantage of all the DASH innovations and options. Also, the PhiBer Accumulator App received a facelift with revamped graphics and integration enhancements.

2020-2021

2020

PhiBer, known for their expertise in ‘Big Bales,’ set a new industry standard, with the AC 5130 and AC 5150, horizontal accumulators capable of handling up to 5-bales and 4 ton carrying capacity. These models feature individual bale weighing capabilities.

2020

PhiBer also launched the VS2208 stacking accumulator which features a trailing hitch in transport, allowing for higher transport speeds and compliance with European road regulations.

2021

PhiBer became the exclusive producer of all Accumulators sold by AGCO. To meet the resulting increase in production demand, PhiBer expanded its operations by constructing an additional warehouse and relocating the DASH production line to a secondary facility.

2022-2024

2022

PhiBer released the 4 Series DASH, the 3 Series Gladiator, and a patented pitch control system.

2023

Growing market demand for PhiBer implements led to the creation of over 30 new positions, filled by both local residents and individuals from neighboring communities.

2024

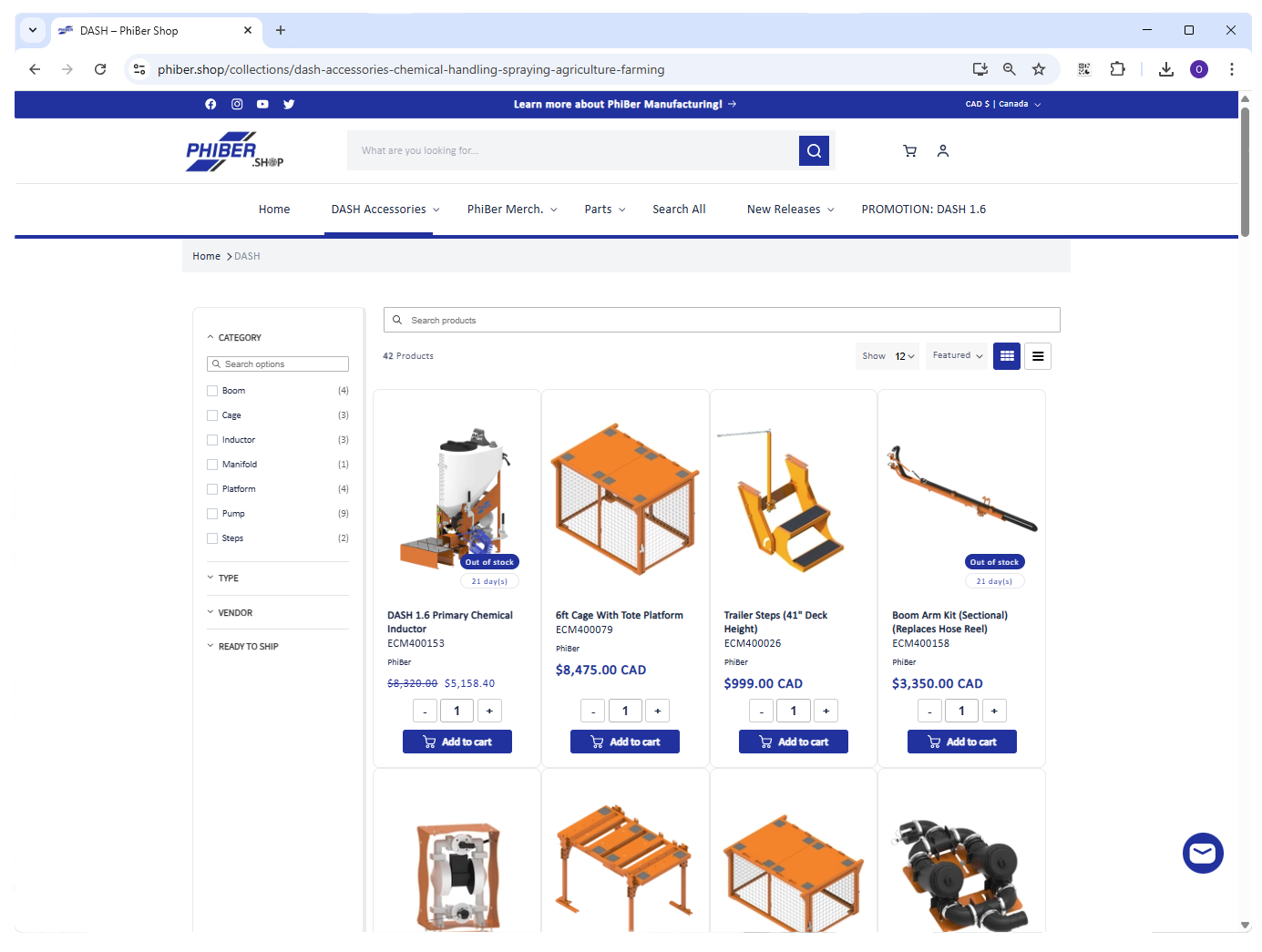

PhiBer introduced the 6 Series DASH, the DASH Carrier (drone trailer), the Centurion, and—last but not least—PhiBer.SHOP: a new online marketplace that brings availability and convenience to a whole new level in the agricultural and liquid handling markets.

2024

2024

Phil Friesen officially retires and sells all of his PhiBer shares to his son Derek. Lawyer Doug Treble oversaw the legal documentation.

2024

More and more large acre-farms are converting to spraying by drones. DASH Carrier does it all, mix chemicals accurately and fast, as well as recharge and refill drones to optimize productivity.

2024

PhiBer proudly launched Phiber.shop, an advanced e-commerce platform designed specifically for farmers. The vast majority of farmers are resourceful, smart, and know exactly what they need. That’s why we created over 3 million configuration options for spraying systems—allowing customers to quickly find and purchase the parts they need, exactly when they need them.

2025

2025

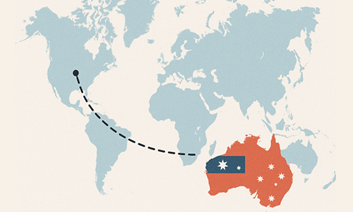

While we remain firmly grounded in Crystal City, Manitoba, 2025 marked PhiBer’s International Expansion as we officially expanded into Australia and established an American headquarters in North Dakota to better serve our international customers.

2025

PhiBer Manufacturing proudly received the AgTech Innovation Award at Ag in Motion for its cutting-edgeDrone Carrier, designed to revolutionize aerial application in agriculture.

2025

PhiBer’s innovative Pitch Adjustable Tilt Kit received U.S. Patent No. 12,338,603, recognizing its unique design that simplifies trenching and crowning with the Gladiator blade.

2025

PhiBer’s DASH Spray Tender System earned a Highly Commended award at Henty Machinery Field Days in Australia for its fast fill times, hands-free mixing, and farmer-friendly design — built to handle demanding spray seasons.

2025

PhiBer’s DASH Carrier was named a Top 10 New Product Winner at the Sunbelt Ag Expo, a leading U.S. agricultural innovation showcase. Recognized for its cutting-edge aerial application support, modular platform design, and efficiency, the DASH Carrier continues to raise the bar in precision ag equipment.

- Choosing a selection results in a full page refresh.

- Opens in a new window.