Introduction

When you need a pump that can handle abrasive, viscous, or corrosive fluids without breaking down, air diaphragm pumps are one of the most versatile solutions on the market. Whether you’re in agriculture, construction, food processing, or wastewater management, these pumps deliver dependable performance in the toughest conditions.

Key Benefits of Air Diaphragm Pumps

- Handles almost any fluid – from thick slurries to chemicals to water.

- Self-priming – can run dry without damage, unlike many other pumps.

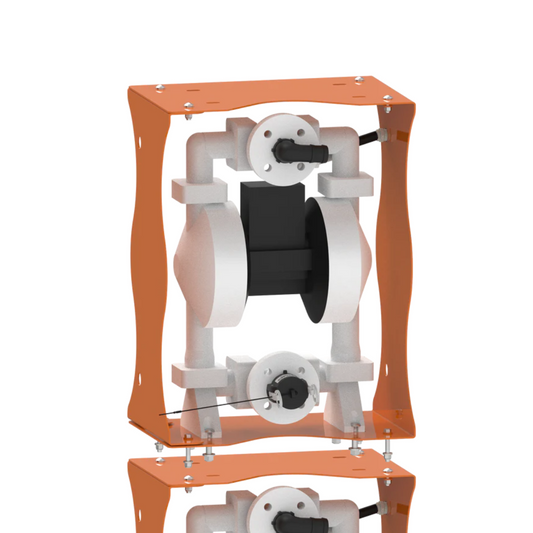

- Portable and compact – no complicated setup, just connect to an air supply.

- Durable design – built to withstand abrasive and corrosive applications.

- Easy maintenance – fewer moving parts compared to other pump types.

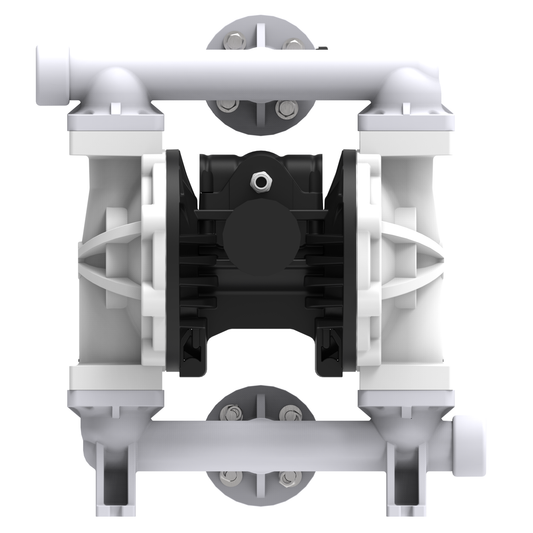

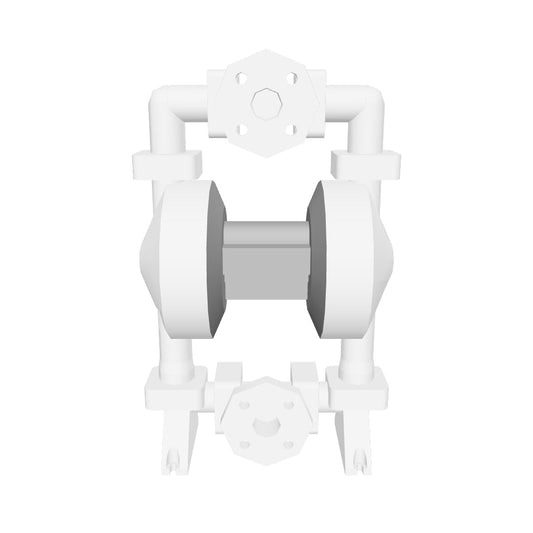

What is an Air Diaphragm Pump?

An air-operated double diaphragm (AODD) pump uses compressed air to move two flexible diaphragms back and forth. This action creates suction that draws fluid into the pump and then pushes it out, all without the need for electric motors or mechanical seals.

This makes them ideal in environments where electricity is unsafe (like explosive atmospheres) or where reliability and versatility are critical.

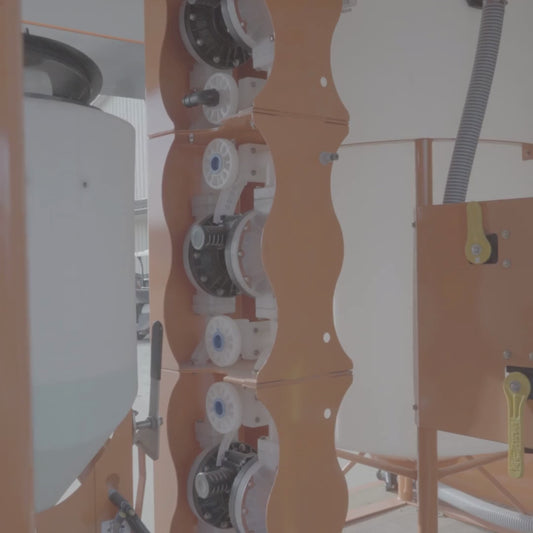

Common Use Cases & Applications

Air diaphragm pumps are widely used across industries:

- Agriculture – transferring fertilizers, pesticides, and irrigation water.

- Construction – dewatering, moving slurries, and handling grout.

- Food & Beverage – pumping sauces, oils, and syrups without contamination.

- Chemical Processing – safely moving acids, solvents, and corrosives.

- Mining & Wastewater – handling sludge, slurry, and other heavy fluids.

How Do They Compare to Other Pumps?

- Centrifugal Pumps – great for large volumes of water, but struggle with thick or abrasive materials.

- Peristaltic Pumps – good for chemical dosing, but less suited for heavy flow.

- Air Diaphragm Pumps – a middle ground: versatile, tough, and easy to move around job sites.

Choosing the Right Air Diaphragm Pump

When selecting a pump, consider:

- Flow rate – how much fluid you need to move per minute/hour.

- Material compatibility – choose pump housings and diaphragms that can handle your fluids (e.g., stainless steel for food, polypropylene for chemicals).

- Port size – make sure it matches your hose or pipe setup.

- Air supply – ensure your compressor has enough capacity for the pump.

Conclusion

Looking for a pump that can handle anything you throw at it? Check out our Air Diaphragm Pumps collection. With rugged construction, simple operation, and versatile applications, they’re the pump you’ll rely on for years.

Frequently Asked Questions About Air Diaphragm Pumps

Q: What fluids can an air diaphragm pump handle?

Air diaphragm pumps are versatile and can handle water, chemicals, slurries, oils, and even abrasive fluids, making them ideal for industrial, agricultural, and food applications.

Q: How do I choose the right size air diaphragm pump?

Select a pump based on flow rate, pipe size, and fluid viscosity. Manufacturers often provide sizing charts to help you find the best fit for your needs.

Q: Can air diaphragm pumps run dry?

Yes. Unlike many electric pumps, air diaphragm pumps can operate without fluid without causing damage, making them perfect for intermittent or unpredictable pumping tasks.

Q: Are air diaphragm pumps suitable for hazardous liquids?

Yes, but only models rated for hazardous or explosive environments should be used with flammable or volatile liquids. Always follow safety guidelines.

Q: How often should I replace the diaphragms?

Diaphragm life depends on the type of fluid and usage. Abrasive or chemical fluids will wear diaphragms faster. Replacement diaphragms are generally inexpensive and easy to install.

Q: Can air diaphragm pumps handle solids?

Yes. Many pumps can move fluids containing solids up to a specified size, making them ideal for slurries, sludge, or chunky fluids.

Q: Do these pumps require electricity?

No. Air diaphragm pumps are powered by compressed air, making them safe and reliable for wet, outdoor, or explosive environments.

Q: How noisy are air diaphragm pumps?

Some models can be loud at higher air pressures, but using mufflers or sound enclosures can significantly reduce noise.

Q: Can I operate an air diaphragm pump vertically?

Most models can run in any orientation—horizontal, vertical, or even upside-down—but always check the manufacturer’s guidelines.

Q: Why choose an air diaphragm pump over an electric pump?

Air diaphragm pumps are portable, self-priming, versatile, and can handle abrasive or corrosive fluids. They also operate safely without electricity, which is essential in hazardous or wet environments.